Ingenious Solutions Await: Browse a Series Of Stacking Conveyors for Sale

Ingenious Solutions Await: Browse a Series Of Stacking Conveyors for Sale

Blog Article

Release the Power of Stacking Conveyors for Ideal Recycling Efficiency

In the globe of recycling, efficiency is vital. Discovering means to make the most of and enhance the process output is a constant search for sector experts. Which's where stacking conveyors come into play. These simple machines hold tremendous capacity, with the ability of reinventing the reusing performance. With their capability to raise sorting efficiency, boost material handling, simplify the recycling process, and boost room application, piling conveyors supply a cost-efficient remedy that can genuinely let loose the power of recycling. Yet exactly how exactly do they achieve this? Well, allow's take a closer look.

Enhanced Arranging Efficiency

One of the key advantages of piling conveyors is their ability to deal with big volumes of products. By automating the arranging procedure, these conveyors can manage a greater throughput of recyclables, decreasing the requirement for hands-on labor and increasing general productivity. This not only conserves time but also decreases the risk of human mistake, guaranteeing a much more precise sorting process.

In addition, piling conveyors permit the segregation of various sorts of recyclables right into separate stacks or containers. This makes it much easier for recycling facilities to process and offer these materials to suppliers that can transform them into new items. By improving the sorting performance, stacking conveyors help make best use of the worth of recyclables, adding to a more profitable and sustainable recycling market.

Boosted Product Handling

Stacking conveyors play an essential function in improving material dealing with efficiency within recycling facilities. These specialized conveyor systems are designed to efficiently transport and stack various types of recyclable materials, such as paper, plastics, steels, and glass. By automating the procedure of moving products from one location to another, piling conveyors not only conserve time yet likewise boost worker safety and security and productivity.

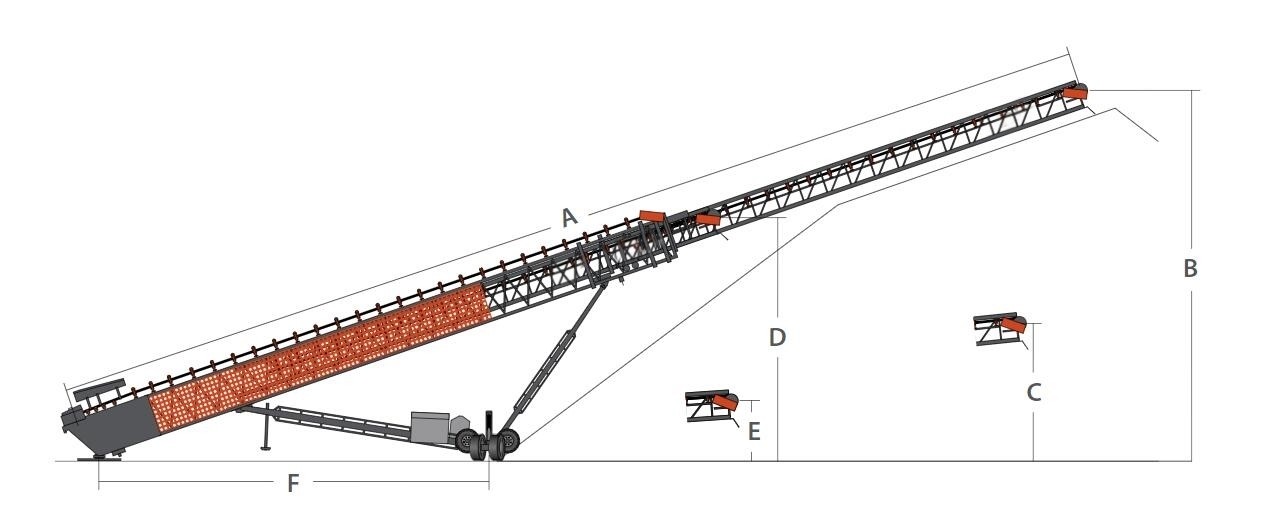

Among the vital advantages of utilizing stacking conveyors for material handling is their capability to handle large quantities of recyclable products. These conveyors are created with adjustable elevations and angles, enabling them to get to higher levels and pile products in an arranged way. This not only makes the most of storage space capacity but likewise makes it easier for employees to accessibility and retrieve products when needed.

Moreover, piling conveyors are equipped with advanced attributes such as variable speed controls and automated sorting systems - stacking conveyors for sale. This enables them to sort and separate various sorts of recyclables as they are transported along the conveyor belt. By streamlining the sorting procedure, these conveyors help to enhance reusing efficiency and decrease the threat of contamination

Furthermore, piling conveyors are created to stand up to extreme environmental conditions frequently discovered in reusing centers. They are constructed with resilient products and geared up with dirt suppression systems to ensure reliable and continuous procedure. This minimizes downtime and Home Page maintenance expenses, additionally enhancing the total material managing effectiveness within the center.

Streamlined Recycling Refine

The implementation of effective stacking conveyors in reusing facilities results in a streamlined recycling process. These conveyors play a critical function in optimizing the total performance and productivity of the reusing operations. By automating the activity of materials, they remove the demand for hand-operated sorting and handling, reducing the threat of injuries and improving worker safety.

Stacking conveyors enable the smooth transfer of recyclable products from one processing phase to another, making certain a continual and smooth circulation throughout the recycling process. They can manage a large range of products, consisting of paper, metal, plastic, and glass, with varying weights and sizes. This convenience enables reusing facilities to efficiently refine different sorts of waste streams, boosting their capability to manage bigger volumes of recyclable products.

Additionally, stacking conveyors promote the partition of various products, ensuring that each recyclable part is directed to its particular processing line. This splitting up not only improves the reusing effectiveness however additionally improves the quality of the end products. By lessening contamination and preserving the stability of the materials, piling conveyors contribute to the manufacturing of premium recycled products that meet the marketplace need.

On top of that, using stacking conveyors lowers the requirement for manual work, enabling reusing centers to reapportion their workforce to even more value-added jobs. This optimization of human sources results in cost financial savings and increased operational efficiency.

Improved Room Utilization

With the application of effective piling conveyors, reusing centers can enhance their space use for enhanced functional efficiency. Piling conveyors are designed to optimize storage space ability by vertically stacking products in a well organized and portable fashion. This allows recycling facilities to maximize their available room, lowering the requirement for added storage space areas and reducing mess on the plant floor.

By utilizing piling conveyors, reusing centers can create a much more effective and streamlined workflow. The capacity to stack products vertically gets rid of the need for wide aisles and large open spaces, liberating important flooring area for other procedures or devices. This improved space utilization not only increases the total effectiveness of the center but also boosts employee safety and security by minimizing the risk of mishaps and injuries brought on by jampacked job locations.

In addition, stacking conveyors make it possible for recycling facilities to keep and process a bigger quantity of materials within a smaller footprint. This is particularly helpful for facilities with restricted space or those wanting to expand their operations without incurring substantial costs for added land or buildings. By maximizing room use, recycling facilities can increase their processing ability, meet expanding demand, and possibly generate higher incomes.

Cost-effective Reusing Remedy

Implementing a cost-effective recycling remedy is crucial for maximizing operational effectiveness and taking full advantage of earnings in more tips here reusing facilities. As the need for reusing remains to expand, it is critical for centers to find means to minimize expenses while preserving top quality outcome. Stacking conveyors use a cost-efficient option by streamlining the recycling procedure and decreasing manual work.

One of the vital benefits of stacking conveyors is their ability to efficiently transport products over cross countries. By removing the need for several conveyors or hands-on handling, piling conveyors minimize the overall price of transportation. Furthermore, these conveyors are created with flexible elevation and inclination, allowing for simple customization to fit the specific requirements of the facility.

Additionally, piling conveyors enhance the sorting and separation process, which is critical for reusing centers. stacking conveyors for sale. These conveyors can be equipped with functions such as magnetic separators, eddy existing separators, and selecting stations, enabling efficient material segregation. This read this post here not just boosts the high quality of recycled materials however likewise minimizes the amount of waste that ends up in garbage dumps

Verdict

Finally, making use of piling conveyors can considerably enhance recycling efficiency by raising sorting effectiveness, improving material handling, improving the recycling procedure, and enhancing area usage. This cost-effective solution supplies many advantages for reusing centers, promoting a more sustainable and reliable technique to squander administration.

To improve recycling productivity and improve procedures, the application of piling conveyors has proven to dramatically enhance the sorting efficiency in reusing centers.Piling conveyors play a critical function in enhancing product managing effectiveness within recycling facilities. Stacking conveyors are designed to take full advantage of storage ability by up and down stacking products in a portable and organized fashion.In addition, stacking conveyors enable recycling facilities to store and process a larger volume of products within a smaller sized footprint. By removing the need for multiple conveyors or hands-on handling, piling conveyors lower the general price of transport.

Report this page